OEM Gasketed Plate Heat Exchanger

We can provide you with the heat exchanger machine suitable for you according to the heat exchange parameters and media you need,our gasketed Plate Heat Exchangers are suitable for all type of industries with multiple applications.Our plate heat exchanger can be used in the field of air-conditioner, stores, petroleum chemicals, boats and ships, food and drinks, iron and steel , recycling of the heat.Our plate heat exchangers are designed to flexibly meet a wide range of needs,and we also have perfect manufacturing and after-sales service to ensure a good customer experience.

- NEW ROC UNO

- China

- 7-15days

- 5,000 production per day

- Information

How gasketed plate heat exchangers work

In a gasketed plate heat exchanger, the plates are fitted with elastomeric gaskets which seal the channels and direct the fluids into alternate channels. The plate pack is assembled between a frame plate and a pressure plate, and compressed by tightening bolts fitted between these plates. The channel plates and the pressure plate are suspended from an upper carrying bar and located by a lower guiding bar, both of which are fixed to the support column. The physical design of the gasketed plate heat exchanger allows easy cleaning, and modification of capacity by the addition or removal of plates.

Standard Materials

For Frame: Carbon steel, stainless steel,

For Plate: Stainless stell ,titanium Plates Stainless steel alloy304,Stainless steel alloy316 Stainless steel alloy C276 or Titanium or SMO

For Gaskets: NBR , EPDM , Viton A, Viton G CR

Why choose Gasketed Plate Heat Exchanger?

Easy to assemble and clean

Highest performance plate

Highest pressure resistance

Longer service life,lower operating costs

High heat transfer efficiency

Application

Food industry: Milk pasteurization Milk and beverage pasteurization, Wine tempering, Bottled water treatment, CIP (Cleaning-in-Place) heating, Reverse osmosis water.

Marine application: Central cooling of the main or auxiliary engines or turbines, Lubrication oil cooling, Recooling of circulated water for cooling cylinders, pistons, injection nozzles, Cooling of Baoder oil, compressor oil and other lubricants, Preheating of lubrication oil and heavy fuel oil, Preheating of seawater for fresh water production, Heat recovery, Heat exchange to air-condition the passengers' cabins and freight spaces

Others: Turbine oil cooler, Chemical industry, district heating, district cooling, swimming pool heating, solar heating.

Maximum pressure and temperature

All models are available with different frame designs and different plate thickness depending on the required design pressure. The maximum temperature depends on the gasket material used, and the working pressure

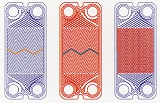

Low angle channel arrangement For lower allowable pressure drop requirement applications

Mixed channel arrangement Optional arrangement to gain the optimized performance

High angle channel arrangement For higher thermal performance and alloable pressure drop requirement applications

model | diameter(mm) | model | Corner hole center distance |

S4A | DN30 | RU30-A | 381*70 |

S8A | DN30 | RU30-B | 656*70 |

S7A | DN60 | RU60-A | 394*126 |

S14A | DN60 | RU60-B | 694*126 |

S20A | DN60 | RU60-C | 894*126 |

S9A | DN65 | RU65-A | 381*192 |

S19A | DN65 | RU65-B | 701*192 |

S31A | DN65 | RU65-C | 1050*192 |

S21A | DN100 | RU100-A | 719*225 |

S22A | DM100 | RU100-B | 719*225 |

S47A | DN100 | RU100-C | 1365*225 |

S37 | DN80 | RU80-A | 1071*238 |

S41A | DN150 | RU150-A | 890*296 |

S42A | DN150 | RU150-B | 890*296 |

S62A | DN150 | RU150-C | 1292*296 |

S43A | DN200 | RU200-A | 791*395 |

S65A | DN200 | RU200-B | 1091*395 |

S100A | DN200 | RU200-C | 1489*395 |

S130 | DN200 | RU200-D | 1891*395 |

S113 | DN250 | RU250-A | 1527*448 |

S121 | DN300 | RU300-A | 1490*480 |

S81 | DN300 | RU300-B | 1080*480 |

S188 | DN300 | RU300-C | 2120*480 |

S145 | DN400 | RU400-A | 1410*660 |

S210 | DN400 | RU400-B | 1901*660 |

S201 | DN500 | RU500-A | 1822*672 |