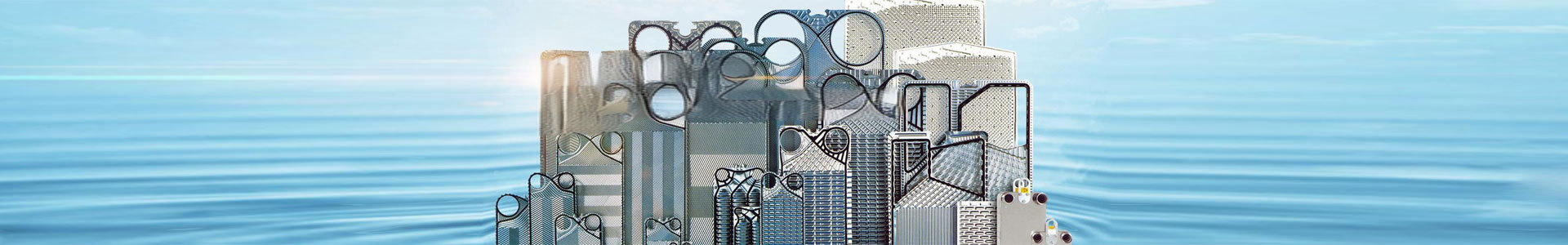

Hisaka Heat Exchanger Plate

Plate heat exchanger is made of alloy plate or stainless steel, The heat transfer plate has a perfect embossing, Choose different materials to withstand corrosion from different media.Because of the variety of embossing can produce variable flow gap.We can provide the perfect heat exchanger plates which can replace the original plate perfectly.In order to ensure traceability of heat exchanger plates, we strictly implement the requirements of ISO9000, strictly control every link of production and conduct strict delivery inspection.

NEW ROC UNO supplies HISAKA heat exchanger plates replacements.

- NEW ROC UNO

- China

- 7-15days

- 5,000 production per day

- Information

(1)We have many models for detachable plate heat exchanger. The plate angle is distinguished between high theta and low theta, chevron is divided into shallow groove.deep groove and super-deep groove which can be assembled to narrow passage PHE, wide passage PHE and free flow PHE in order to be applied in different fields and fluids.

(2)The heat exchanger plate minimizing energy consumption and improving work efficiency,contributing to lower environmental impact and reduced cleaning requirements.

(3)High energy operational efficiency enables high return on low investment,simple installation is a compact design.

(4)Our unique plate shape coupled with suitable plate model design improves heat transfer efficiency and enables thermal mixing design with better heat transfer performance and pressure drop.

EX11,EX15,LX10A,LX20,LX20A,LX30A,LX40,LX50A |

RX13A, RX30A, RX70,SX41,SX43,SX90,SX90M |

UX01,UX10,UX10A,UX20,UX20A,UX30,UX30A,UX40,UX40A,UX80,UX90 |

Material | Thickness | Corrosion resistance | Applicable |

304 stainless steel | 0.4mm to 0.8mm | low corrosion resistance | HVAC pplications |

316L Stainless Steel | 0.4mm to 0.8mm | high corrosion resistance | acids, chlorides,sea water,and chlorine chemicals |

Titanium | 0.5mm to 0.6mm | very high corrosion resistance | acids, chlorides,sea water,and chlorine chemicals |

Hastelloy C276 | 0.6mm to 0.8mm | excellent corrosion resistance | chemical processing, pollution control, pulp and paper production, industrial and municipal waste treatment, and recovery of sour natural gas |

SMO 254 | 0.6mm to 0.8mm | a high-alloy austenitic stainless steel | seawater and other aggressive chloride-bearing media |